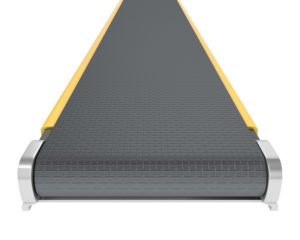

Conveyor belts are an incredibly common piece of machinery in the industrial and manufacturing world, specifically in food processing plants. However, without proper maintenance, they can easily fall apart and need repairs or replacements. Here are a few quick tricks for keeping your conveyor belts up and running as efficiently as possible.

Conveyor belts are an incredibly common piece of machinery in the industrial and manufacturing world, specifically in food processing plants. However, without proper maintenance, they can easily fall apart and need repairs or replacements. Here are a few quick tricks for keeping your conveyor belts up and running as efficiently as possible.

- Keep it clean:

Dirty conveyor belts are more likely to slip and reduce the carrying capacity of the belt. Grime and buildup on the individual components can also reduce the life of both the motor and the belt. Conveyor belt cleaning systems are designed to clean your belt thoroughly so that it functions at its best. Steam cleaning systems eliminate chemical residues while sanitizing the surface being treated. Because so little water is consumed, approximately 1.5 quarts per hour, it’s virtually “mess free”. Conveyor belt cleaning systems range from steam cleaning systems to dry vapor steamers. - Evaluate your needs:

It’s important to carefully consider what you’ll be using your conveyor belt for before you choose a certain type or model. The weight of your product, speed, direction, and material are all important factors that should be considered before investing in a conveyor belt. If you’re unsure, talk to the professionals at a conveyor manufacturing company to discuss your options. But the fact remains that buying the belt that suits your needs can significantly add to its lifespan. In fact, some experts recommend getting a belt that can handle more than what you will need. That way, you can increase production while preserving the lifespan of the belt. - Inspect the belt regularly:

If your conveyor belt isn’t at the right level of tension, it can cause slippage and reduce its lifespan. That’s why it’s critical to perform routine belt inspections. If the belt is too loose, tighten up the tension to eliminate any further issues. Keep in mind that if you’re loading weights onto the belt that exceed its recommended weight capacity, it will cause irreparable damage such as belt, bearing, and motor failure. It can also bring your production schedule to a screeching halt.

Ultimately, these are just a few ideas to help you keep your conveyor belt working at its best. You should always consult the owner’s manual for additional preventative maintenance tips. For more information about conveyor belt cleaning systems, contact Falcon Prosolutions, Inc.